SPINNING

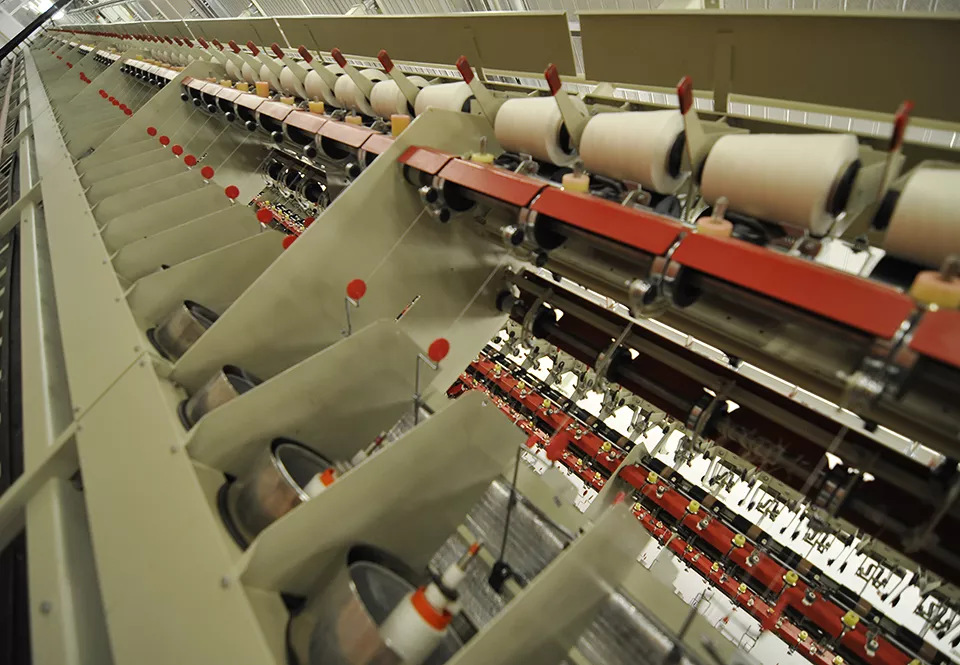

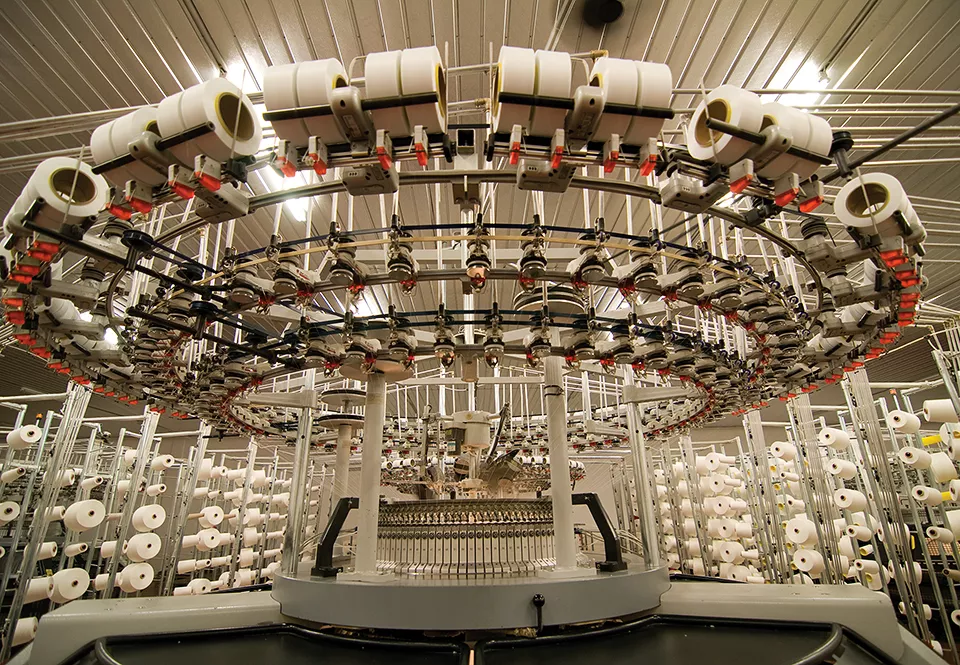

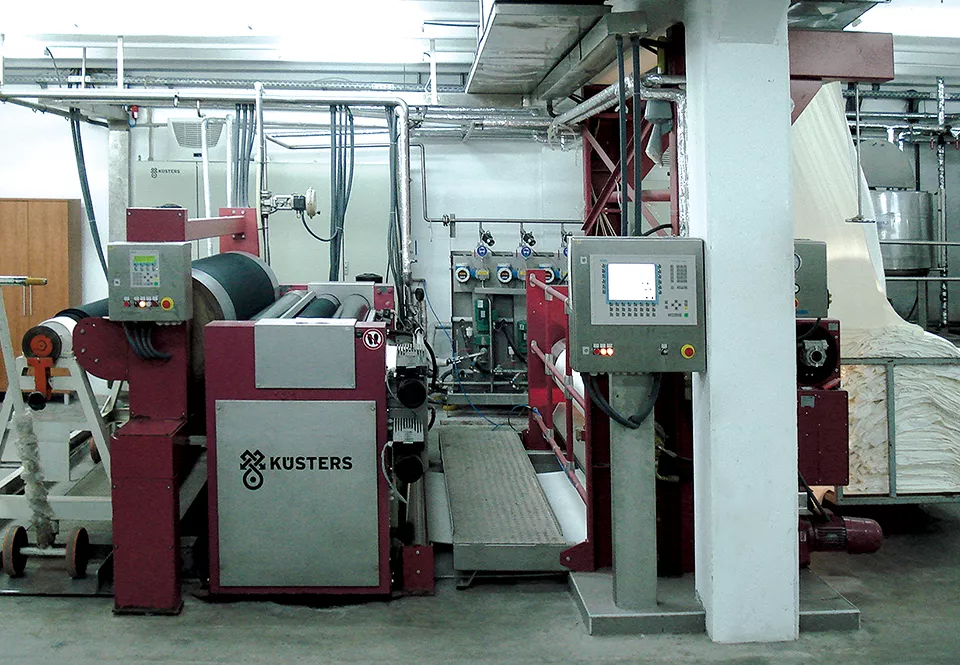

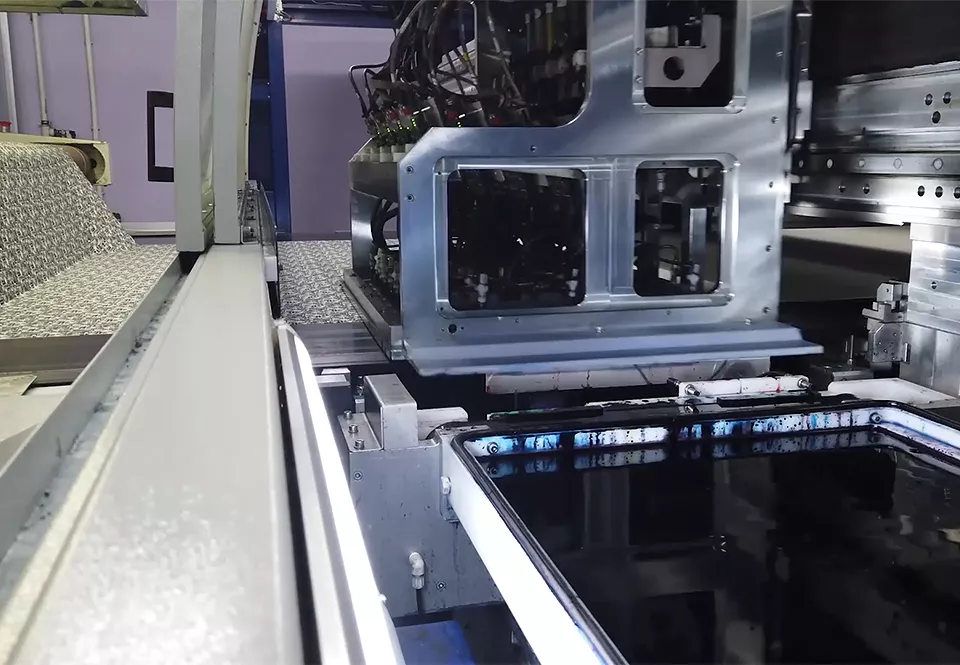

Our modern facilities deliver highest quality 100% or mixed Compact/Siro Ring, Vortex (MVS) and Open-end yarns.

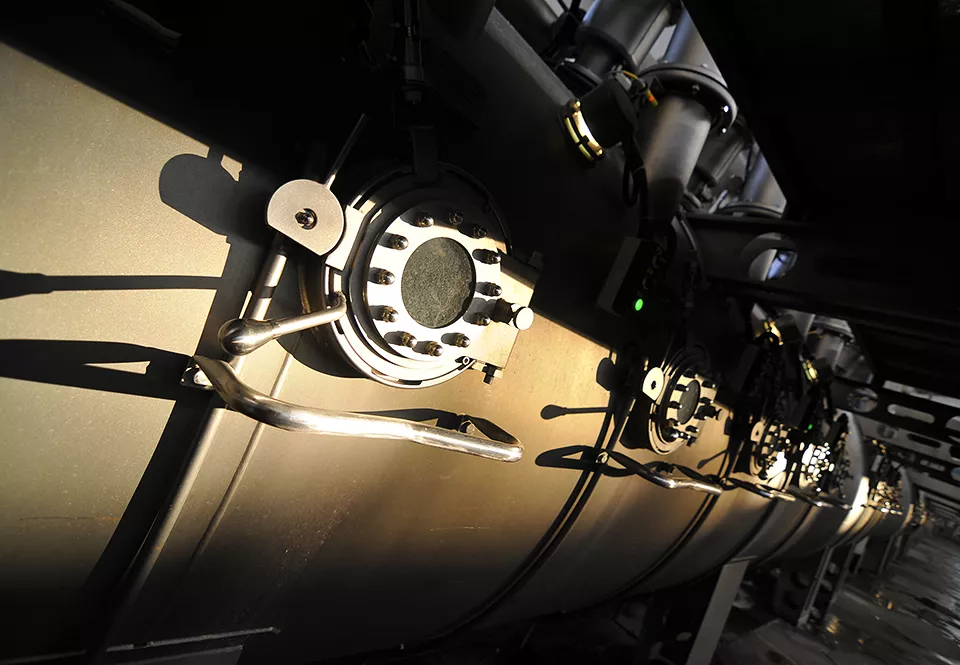

We know that only the best raw materials, right production methods and strict quality control principles yields the highest quality products. That’s why we select the best raw materials for production and process them all with utmost attention to detail.

Located in Niğde, our yarn spinning facility is situated in a 172,000m2 area with 50,000m2 enclosed space. Together with standard and mixed type yarns, our daily production capacity has reached 50 tonnes.